Company News

India’s largest life-saving medical equipment facility progresses to the next level

Pushing the boundaries over, AML becomes an aggressive player in Atmanirbhar Bharat initiative with its new gregarious production facility.

Sound medical infrastructure is the backbone of a flourishing medical industry. The responsibility lies not only in creating technologies but also in innovating newer equipment that supports the dynamic medical care. Taking this view forward, Allied Medical Limited (AML) has always been abreast with technology, and has been attuned to the growing and changing demands of the medical industry. The Company has taken futuristic steps to establish a state-of-the-art facility that undertakes manufacturing of the complete range of life-saving medical equipment.

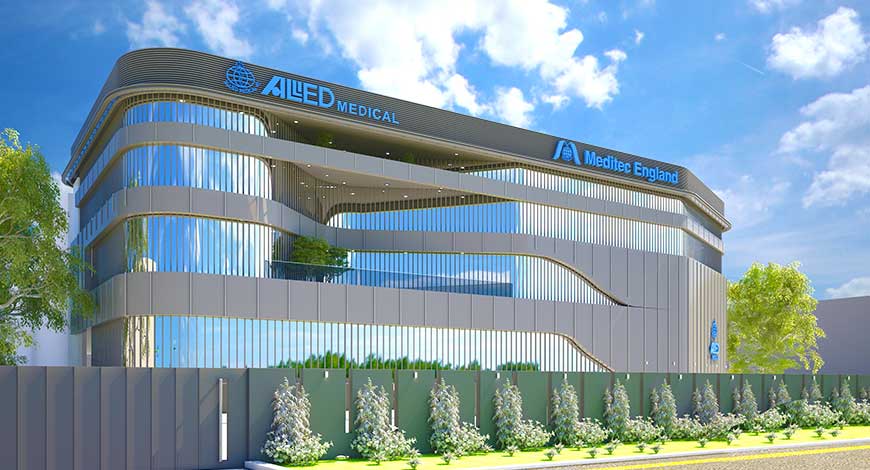

Spread across 200,000 sq. ft. production floor space, this facility is the largest and the most modern facility in India for manufacturing life-saving medical devices. The plant is an approved green field facility under the Production Linked Incentive (PLI) scheme of the Government of India.

This facility is at a distance of 90 minute-drive from New Delhi International Airport, located at Karoli Industrial Area, Bhiwadi, Rajasthan. This facility marks the advent of AML into the league of the largest critical manufacturing plants within India. The manufacturing plant will be operational 24/7 for the production of:

- Ventilators;

- Anesthesia machines;

- Patient monitors;

- Infusion pumps;

- Defibrillators; and

- Many more medical products that are in the pipeline.

AML has already carved a name for itself in the industry owing to its vast product range, high quality of products, and flawless after-sales service. The new plant in Bhiwadi will accentuate the company’s manufacturing capacity manifolds. The facility has dedicated departments for all heads, and the most critical one, i.e., quality-control division, has been strategically placed for optimum output. Most of the components are designed and manufactured at in-house machine shop, assembly and calibration stations.

The new facility has a clean area, service facility and a strong dedicated R&D division that focuses on using new and existing technologies to develop innovative solutions that answer today’s healthcare needs at the most affordable cost to our citizens. Currently, our spending on R&D projects has been five percent of our annual turnover. This figure will go up in double digits for the R&D projects in the new facility. With an increased capacity, AML plans to manufacture parts, components, sub-assemblies, and complete devices to not only cater to India but also to meet global demand. We are building a futuristic manufacturing workforce with our comprehensive training program and next-generation manufacturing techniques to tread toward our goals.

Apart from the manufacturing facility, we also understand intensive care and know that the medical staff in operating theaters plays a crucial role in the management and upkeep of the equipment that is expensive and life-saving in nature. It is imperative to educate and train the staff on both aspects of application and maintenance.

Being a manufacturer, we have earmarked a full-fledged training center and conference hall in the new facility to conduct regular workshops for training, knowledge-building, maintenance, troubleshooting, and appraising for new technologies. This program will create a more technical work force to cater to the patients professionally and confidently. The new facility has a designated area where the entire product range is displayed to provide practical workshops and hands-on training of products for better grasp and operational knowledge.